Aren’t you overcome with nostalgia when you think of the childhood games you played? For me Jeopardy is that game. The clues are presented in the form of answers and the contestants phrase their responses in question form -the game is a lot tougher than it actually sounds. The business transactions between an operator and MRO (Maintenance, Repair and Overhaul) provider is like playing a game of Jeopardy. An airline operator knows that he needs to keep his airplane up and running but still hasn’t figured out the best option to do so. The MRO provider knows that the transition time to carry out maintenance activities on a part or whole aircraft needs to be as low as possible but are still clueless on how to achieve such strict timelines. It boils down to optimized maintenance activities. Let us analyze the growth of an operator and MRO provider over the years to find the question to this answer.

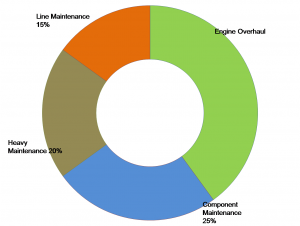

>Over the years the Aviation Industry has grown leaps and bound with regard to maintenance activities. For many years maintenance was viewed predominantly as the activity and cost of the asset operator. But with technological advancements, the approach started to change and airlines began to look for areas of cost reduction and outsource work. In fact, a number of operators established separate operational entities for MRO operations. The MRO industry diversified with large number of companies showing interest in carrying out maintenance activities.The size of global MRO industry is expected to hit US $ 60 billion in 2017. With growing interest in the field of maintenance MRO providers are also expanding their roles, although, within four main services: Engine Maintenance, Component Maintenance, Heavy Maintenance and Line Maintenance. The trend of incurring investments for outsourced maintenance activities is inclined towards Engine and Component Maintenance while Line Maintenance has taken a back seat even though there are investment plans in this area as well

Source: ICF SH&E Analysis

With technological advancements, complex optimization, decision support systems, spiraling cost of labor and labor intensive processes, MRO industries are on the verge of significant change, not only in who performs maintenance but more importantly how maintenance is carried out. This change in behavior is the best possible link to find the missing questions of their answer. MRO providers have started to work with their operators more aggressively to find the best possible solution for both of them. This approach has unraveled significant savings which were later used for maintaining better service levels. In order to achieve the goal both parties have started to follow an integrated approach where people, processes and technology are connected, thus trying to fine tune and optimize every process in the supply chain to meet their objective.

One such initiative started by the MRO providers was the part exchange services. It enables the operator to receive high value critical parts in a short span of time to keep the fleet up and running. The MRO provider, based on its prior experience maintains a database of frequently removed parts and develops a dedicated inventory of replacement components. This is helpful during AOG(Aircraft On Ground) conditions where an operator can run into lossesup to $ 20-25 billion in a year, according to an estimate in 2013. The advantage the operator gets is that the lead time to receive certified parts is reduced considerably and hence he pays only the repair and other costs.

The key benefits of exchanging parts are as follows:

1) Reduced provisioning and inventory holding cost of the operators.

2) Better management of the component repair cycle which reduces the operators need to carry excess inventory to cover parts that are being repaired. It also cuts down on the time and effort required to manage vendors, approve repair quotes, ship and track parts, and process repair invoices.

3) For the MRO provider, it’s about accurate assessment of the costs – since the MRO is locked into a fixed revenue model, they need a good and accurate understanding of the costs involved in running the exchange program ; the costs would accrue in the form of inventory holding costs as well as the repair costs.

4) Better Customer Service from MRO in terms of scheduled commitment and comprehensive offering in terms of certification and warranty of exchanged parts.

It is very important for technology to support business operation which integrates people and processes. Ramco Aviation ERP supports such complex business operations. It offers the flexibility to capture exchange programs as contracts, address the exchange valuation policies, track cost of various transactions involved, efficiently account for the same online and manage the pricing, billing and measure the effectiveness of these exchange programs.Ramco Application has rightly captured the concept of exchange to make its ERP suite even more powerful.