Navigating the Electric Roadmap: ERP’s Role in Electric Vehicle Manufacturing

Published :

The automotive industry is amidst a monumental shift towards sustainability, with electric vehicles (EVs) leading the charge. The EV market is projected to grow from $500.48 billion in 2023 to $1,579.10 billion in 2030 at a CAGR of 17.8% during the forecast period. As the demand for EVs escalates, manufacturers grapple with the twin challenges of meeting market expectations and staying ahead in the innovation race. In this dynamic scenario, Automotive ERP solutions emerge as indispensable tools, orchestrating operations, boosting efficiency, and steering innovation across the entire spectrum of electric vehicle manufacturing - from conceptualization to consumer delivery.

The inception of an electric vehicle commences with conceptualization and design, where ERP software act as enablers for seamless collaboration among diverse teams. Bridging gaps between researchers, designers, engineers, and product managers, Automotive ERP facilitates real-time collaboration through the process of Research, Prototyping, New Product Costing, and the creation of Engineering items and Bills of Materials (BOMs). This centralized platform accelerates decision-making and design iterations.

The complex supply chain dynamics inherent in electric vehicle production necessitate precise management, and Automotive ERP solutions offer a panoptic view of the supply chain. From managing inventory levels to tracking orders and optimizing procurement processes, ERP software provides the transparency needed to enhance agility. Incorporating lead times for procurement and well-defined sourcing rules, Automotive ERP solutions become pivotal in agile material planning.

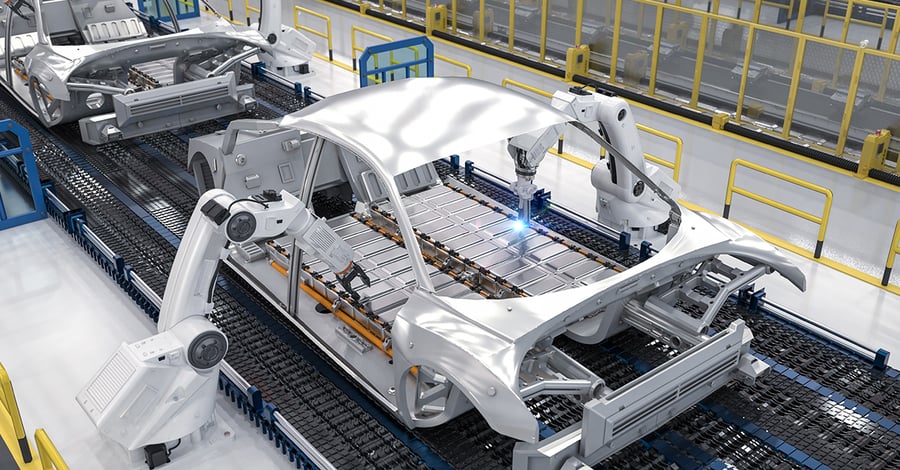

In electric vehicle production, where precision is paramount, ERP Software play a pivotal role in optimizing manufacturing processes. From scheduling production to monitoring workflow and ensuring resource efficiency, Automotive ERP solutions contribute to maintaining consistent manufacturing standards and quality control. Integration with automated production line sensors and provisions for rework order cycles further enhance the manufacturing module.

To stay ahead in the ever-evolving landscape of electric vehicle technology, innovation is non-negotiable. Automotive ERP solutions support Research and Development (R&D) endeavours by providing tools for project management, budgeting, and resource allocation. A robust Engineering Change Management module, integrated with Product Lifecycle Management (PLM) software, becomes a crucial feature in driving R&D initiatives.

The electric vehicle industry, with its unique set of challenges, demands strict adherence to regulatory requirements and sustainability standards. Automotive ERP systems assist manufacturers in staying compliant by ensuring accurate record-keeping and reporting. Support for government schemes like ‘FAME II’ in India and integration with portals such as ‘Vaahan’ is a testament to the flexibility and adaptability of ERP software.

As electric vehicles transition from production to consumers’ hands, effective Customer Relationship Management (CRM) becomes imperative. Automotive ERP solutions with CRM modules empower manufacturers to manage customer interactions, track post-sales support, and collect valuable feedback. Comprehensive dealer management features are essential to handle orders, claims, and service delivery effectively.

In the competitive landscape of electric vehicle manufacturing, ERP software emerge as catalysts, driving innovation and agility from the conceptualization of a vehicle to its delivery to consumers. By streamlining processes, fostering collaboration, and offering real-time visibility, Automotive ERP systems empower manufacturers to navigate the challenges of the EV industry successfully. As the demand for electric vehicles continues to surge, businesses leveraging ERP software solutions are poised to thrive in this era of sustainable and technologically advanced transportation.

Enterprise asset management (EAM) involves the management of mission critical assets of an organization throughout each asset's lifecycle. EAM is used to plan, optimize, execute, and track the needed maintenance activities with the associated priorities, skills, materials, tools, and information. The aim is to optimize the quality and utilization of assets throughout their lifecycle, increase productive uptime and reduce operational costs.

Enterprise asset management (EAM) involves the management of the maintenance of physical assets of an organization throughout each asset's lifecycle. EAM is used to plan, optimize, execute, and track the needed maintenance activities with the associated priorities, skills, materials, tools, and information.

The software helps in effective maintenance of assets through preventive, predictive, shutdown and breakdown maintenance strategies. The system also helps enterprises mitigate equipment risks by enhanced safety standards. The streamlined operations and improved asset performance helps organizations increase their investment effectiveness.

EAM is important because it helps organizations track, assess, manage and optimize asset quality and reliability. Asset intensive Organizations have hundreds, thousands, even millions of assets which needs to be maintained to maximize / optimize life of these assets to increase the return on investment.

The key features of effective EAM are:

Asset Intensive companies under the following Industries :

Contact us for a meeting and schedule a demo

This differs on case to case basis, based on the type of installation and unique industry specific requirements. Contact us for a meeting and schedule a demo.

This differs on case to case basis, based on the type of installation and unique industry specific requirements. Contact us for a meeting and schedule a demo.

Stay Connected, follow us on LinkedIn / Twitter to know more about EAM Software latest trends.

All Rights Reserved. © Copyright 2024. Ramco Systems.