4 Key system capabilities to manage your OEM’s digital technical documentation

Published :

Engineering & technical records department spends a considerable amount of effort and time whenever they deal with OEM technical documents and manuals. Sometimes, it could be the induction of a new set of documents and manuals, and at other times, it could be the revision of existing contents and manuals. And if the documents are in PDF format, then a lot more effort is required. While pursuing a digital technical documentation program, a practical evaluation of content management system’s capabilities is essential to improve the operational efficiencies not only within the engineering & technical records department but across the downstream value chain.

Organizations can unlock value from OEM’s digital technical documents by ensuring the following 4 key capabilities are available in the content management system.

Capability 1: Ability to ingest and process SGML/XML-based documents complying with iSPEC 2200 and S1000D standards.

OEMs are moving their technical documentation and manuals, especially for their new generation fleet, to S1000D standards. However, for the significant number of existing fleets and engines, they are still managed with iSPEC 2200 standards. It becomes imperative then for the content management system to be compatible with both the standards. The iSPEC 2200-based technical documents are supported by both SGML and XML versions. The content processor should be able to ingest the documents in these formats and render the output in HTML for an interactive user experience.

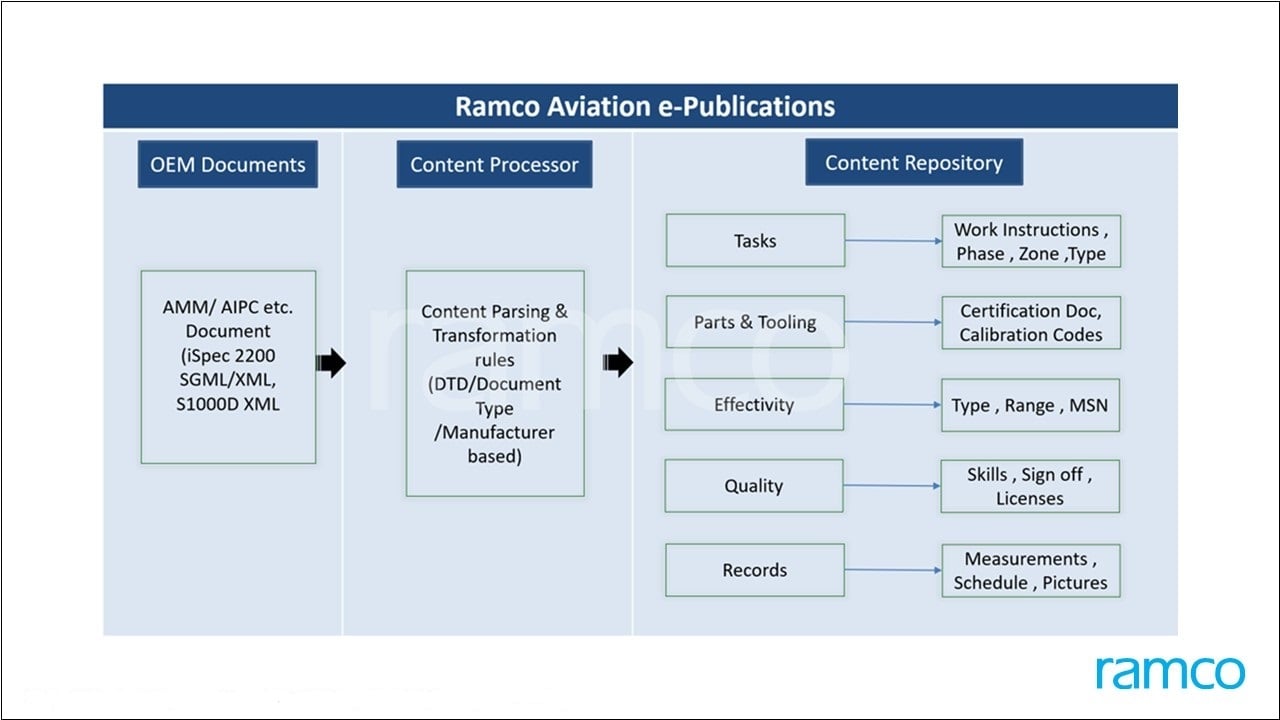

Fig. 1: Building Content Repository

Content processors should provide configurability to enable parsing of the documents. This is essential to manage the variation in documents across OEMs and the variation in formats within the OEM documents such as AMM, AIPC, etc. Content processors with advanced capabilities to parse documents at DTD (data type definition) level, with graphics & images, helps in building and managing the content repository efficiently (refer Fig. 1). These contents can be leveraged to automatically set up metadata definitions like tasks, parts, tools, etc. in M&E System.

Capability 2: Ability to customize the contents to add additional texts, tables, formulae, and graphics.

In the pursuit of improving efficiency and quality, organizations must customize the task cards based on their expertise and specific knowledge. Organizations could predefine the templates for task cards and import the content from OEM documents into the appropriate sections. Task card publisher must be able to render the OEM content in an interactive (WYSIWYG) editor for the engineering team to include additional contents in form of text, tables, formulae, and graphics.

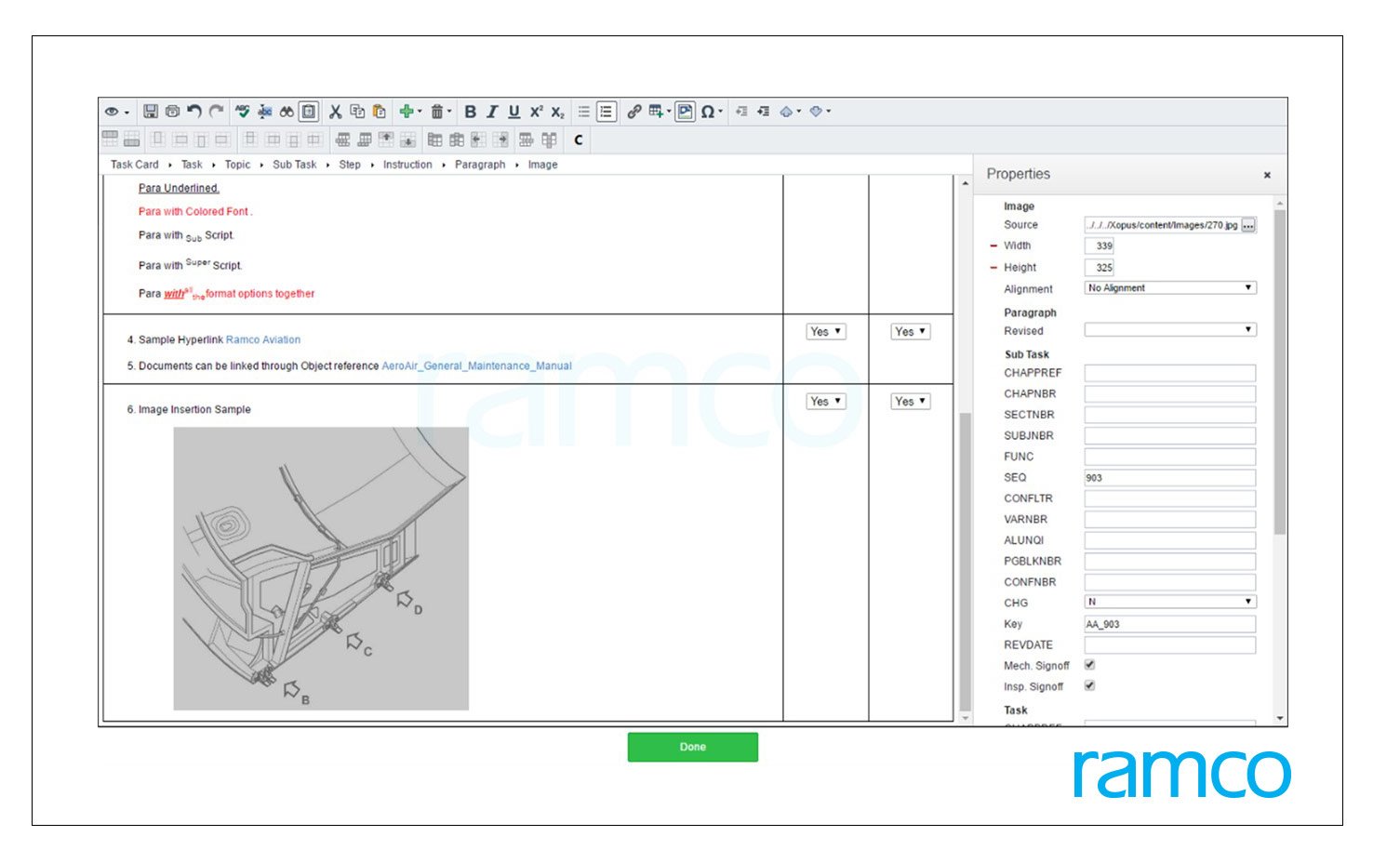

Also, it should have the capability to allow customization by letting users add color codes, symbols, tabular content, videos et al (refer Fig. 2). The engineering team must be able to add additional sign-off blocks based on independent inspection criteria or critical work steps. Effective customization can aid the mechanics to input general observations, texts, measurement numbers and make way for the organization to go paperless.

Fig. 2: Customizing With Image Insertion

The customizations done over the OEM content should be tracked efficiently so that it can be re-applied whenever the OEM content undergoes any revision. This will eliminate the need to redo the customization and conserve the engineering team’s effort and time.

Capability 3: Ability to manage the document revisions, with retention of customization and approval workflows.

OEMs publish document revisions periodically. The revised versions are available on their online document management portal and are provided to their customers directly. The engineering department spends plenty of time and effort to process and regularize the documents according to their operational standards. The key challenge is to identify and analyze the revised/impacted sections and carry out the necessary impact analysis. A content management system’s ability to automate this entire process reduces the errors and the effort and time spent on it.

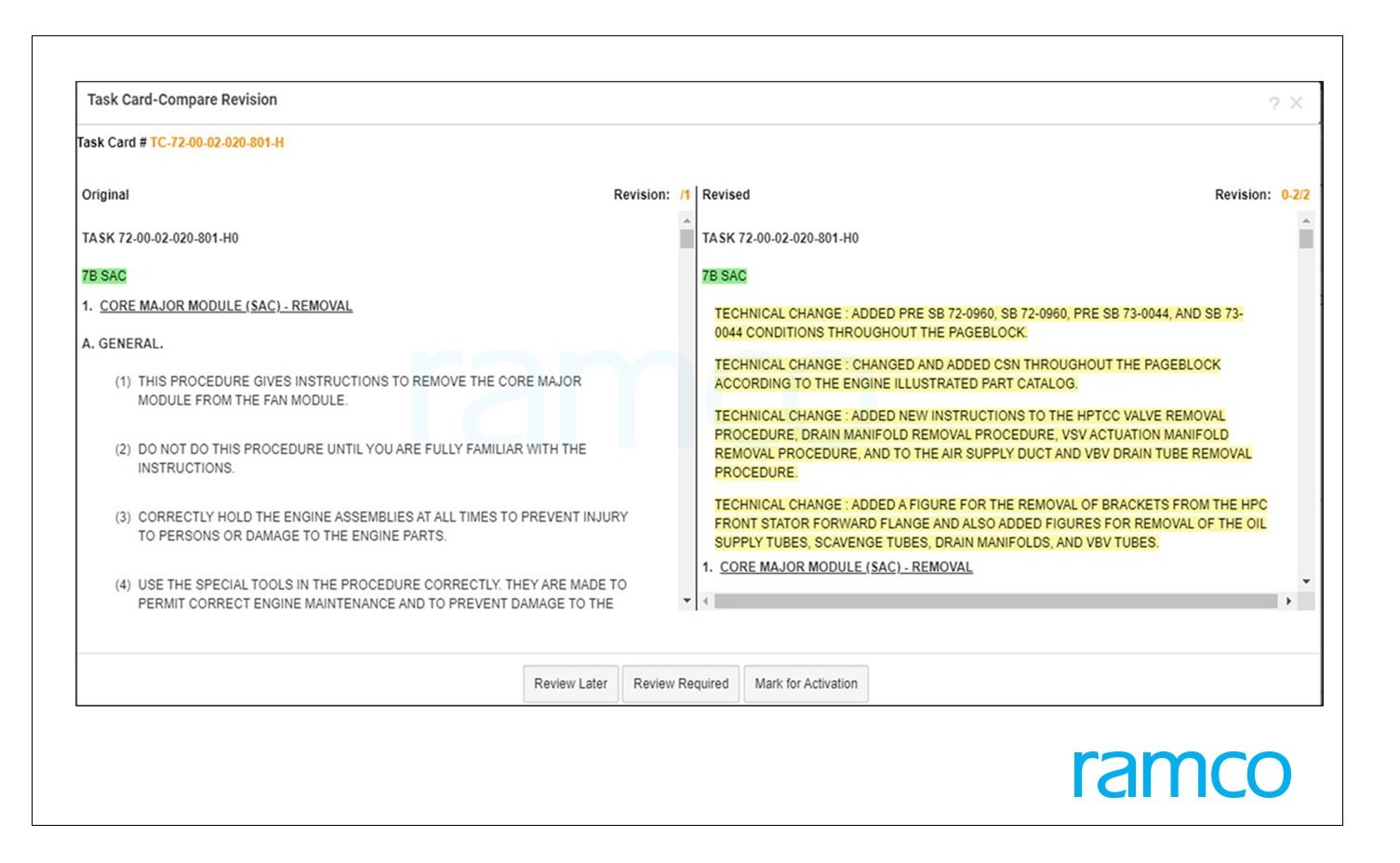

New revisions then should be processed as per capability #1 that we discussed above. Post ingestion, the revision assessment engine must compare the versions and generate the changeset. Changes with new data sets must be processed as mentioned under capability #2 which can be added to the content repository. The changeset should be presented to the engineering team for a side-by-side comparison to generate the final impact assessment report (refer Fig. 3). The engineering department should also have the flexibility to view the customizations done and to re-apply them to the new version.

Fig. 3: Revision Comparison & Assessment

Inbuilt workflow engines need to provide extensive configurability to set up the automated routing notifications, reviews, and approvals. The entire process has to be tracked systematically and an audit trail of the events ought to be maintained for quality and regulatory purposes.

Capability 4: Ability to publish the documents effectively to digitize work execution.

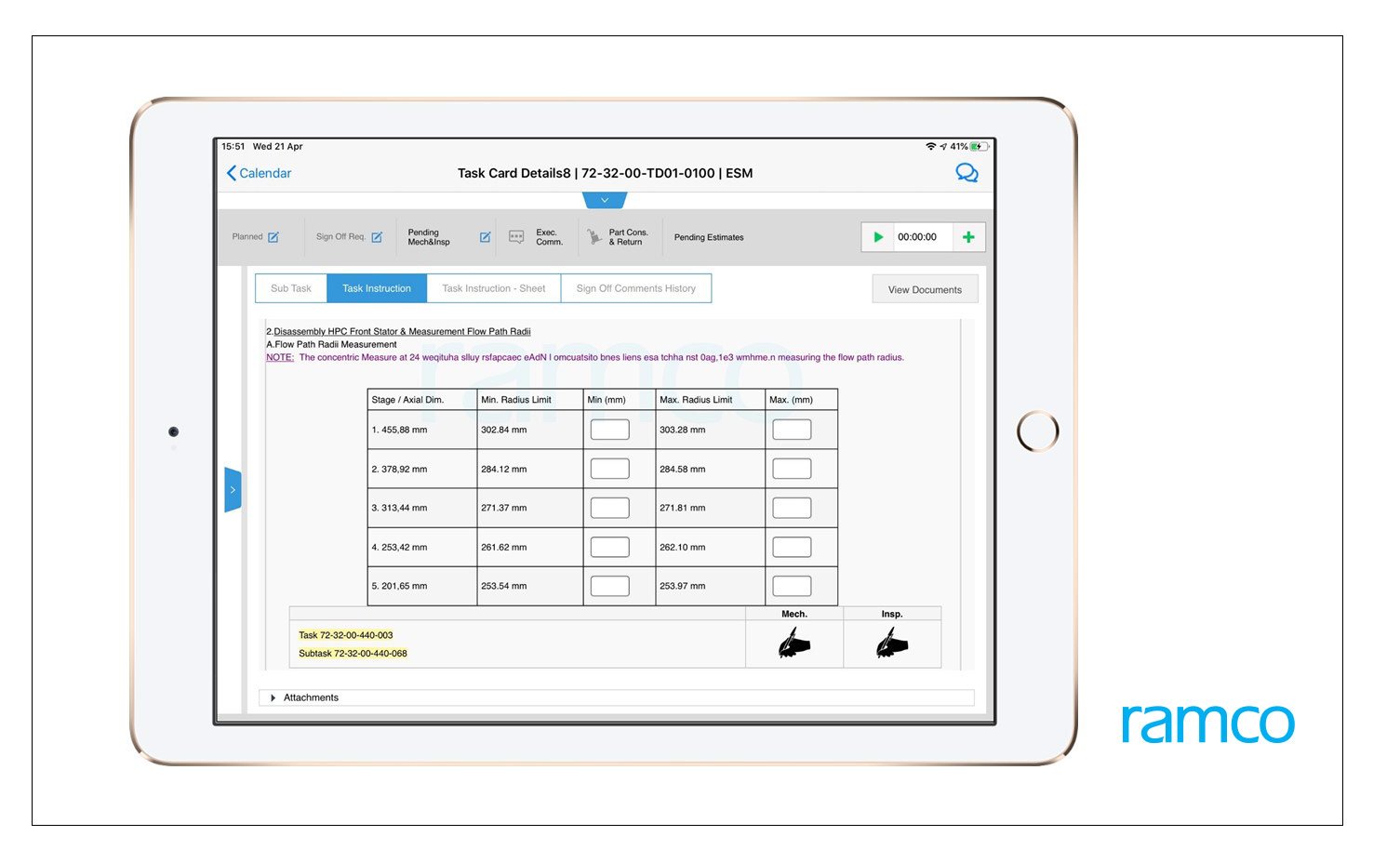

The content management system should let the engineering department provide authorized users access to consume the approved technical documents and manuals. It should have the ability to render the documents on the desktop, as well as mobile devices. The integrated content of the job cards, combining OEM and internal customization, should be made available in an interactive format (refer Fig. 4). From the job cards, mechanics must be able to navigate across multiple documents seamlessly and carry out a universal search across the documents.

Fig. 4: Interactive Technical Publishing

Intelligent authoring & publishing enables the users to record inputs like measurement values, visual observations, photographs, etc. under appropriate sections in the job cards. The interactive job card can guide the users to mandate to input data where feedback is required, ensure all the fields are filled, all the steps are signed-off, and highlight any incomplete fields. This input data collected can be stored in a digital format which can later be leveraged for data analytics.

Key step in achieving digital MRO

With ATA Spec 2000 Chapter 18, the job cards can be exchanged through EDI format across organizations. A right digital documentation strategy allows the mechanics to perform their jobs digitally from their place of work, thereby significantly improving operational efficiencies and helping the organizations go paperless.

Together, the 4 key capabilities can unlock the potential value offered by iSPEC 2200 / S1000 D standards and SGML/ XML protocols that paves the way to achieve the Digital MRO vision.

This blog is a part of Digital Aviation MRO blog series. You can check out the previous blog in this series here. For any further clarifications you can reach out to us at contact@ramco.com

All Rights Reserved. © Copyright 2024. Ramco Systems.